Coating Composition Analysis VR-XD 1000 for Alloy & Plating

The VR-XD 1000 is an advanced XRF coating thickness analyzer designed for precise multi-layer coating composition and plating bath analysis. It excels in measuring complex-shaped, with its micro-focus X-ray source, EFP algorithm, and distance compensation, ensuring high accuracy for industrial quality control.

Specifications

Coating Thickness & Composition Analysis

Analyzer Type

550 × 750 × 650 mm

Machine Dimensions

Up-to-Down Optical Path

Optical Path Design

100 kg

Net Weight

0-90mm (with distance compensation)

Measuring Distance Range

AC100V-240V, 50/60Hz

Power Requirements

0.01mm²

Minimum Measuring Spot

Advanced EFP Algorithm

Software Algorithm

High-precision manual platform

XY Platform

Multi-point testing, complex shape adaptation

Special Features

VR-XD 1000 Coating Thickness & Composition Analyzer: Precision for Complex Industrial Applications

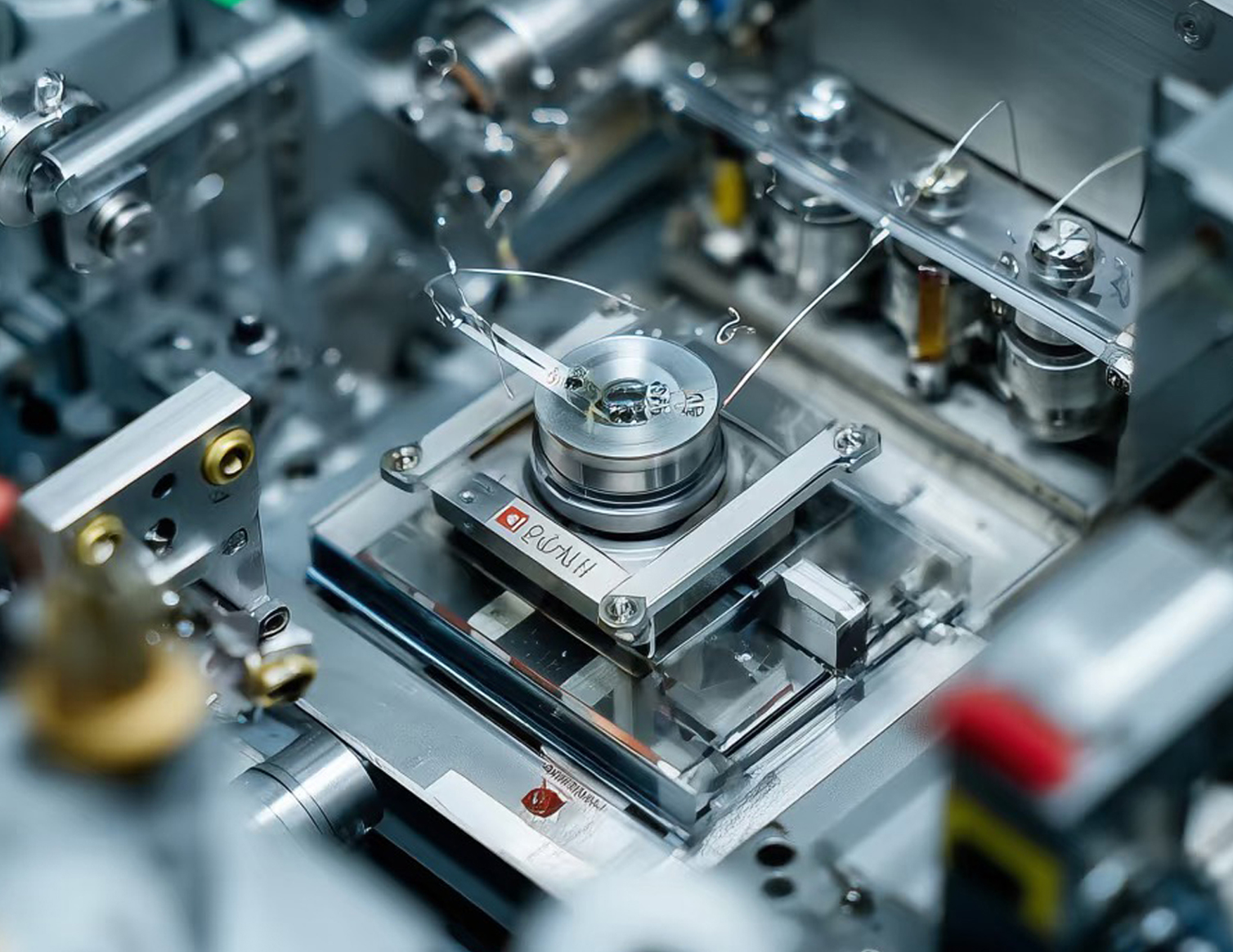

The VR-XD 1000 is a high-performance X-ray fluorescence (XRF) analyzer engineered to deliver exceptional accuracy in coating thickness measurement and composition analysis for a wide spectrum of industrial plating and alloy applications. Designed to tackle challenging measurement scenarios, it is the ideal solution for quality control professionals dealing with complex geometries, recessed areas, and multi-layer coatings.

Its innovative up-to-down optical path design allows for the non-destructive testing of irregularly shaped samples that cannot be easily measured by conventional benchtop instruments. At the core of its analytical prowess is a micro-focus X-ray tube and an advanced EFP (Elite Fundamental Parameters) algorithm, which work in concert to achieve precise results on spots as small as 0.01mm². The system is further enhanced by an intelligent zooming device and a sophisticated distance correction function, compensating for varying measuring distances up to 90mm to ensure consistent accuracy on curved or uneven surfaces.

The VR-XD 1000 supports the simultaneous analysis of multiple layers and elements within those layers, providing detailed insights into complex coating structures, including the thickness of the same element present in different strata. Its advanced spectrum decomposition technology minimizes interference from adjacent element spectra, significantly improving test accuracy and lowering detection limits.

Built for reliability and ease of use in industrial environments, the instrument features a robust design with a high-precision manual platform for accurate sample positioning. It represents a perfect blend of powerful analytical capabilities and practical functionality, making it an indispensable tool for the automotive, aerospace, electronics, and metal finishing industries where verifying coating integrity and composition is critical for product performance and compliance.

Rapid Testing

Get results within 30 seconds, greatly improving efficiency.

Versatile Applications

Suitable for a wide range of use cases.

High-Precision Analysis

Advanced algorithms and optical systems ensure accuracy and reliability.

Non-Destructive Testing

Non-contact analysis preserves samples intact.

VR-XD 1000: Unmatched Versatility for Complex Coating & Alloy Analysis

The VR-XD 1000 is engineered to overcome the most challenging industrial measurement scenarios, providing exceptional accuracy for coating thickness and composition analysis on large, complex, and irregularly shaped samples. It combines powerful hardware with intelligent software to deliver reliable, non-destructive testing for stringent quality control.

Core Advantages:

- Handles Oversized & Complex Samples: Unique up-to-down optical path design allows for precise measurement of workpieces and components with recesses, curves, and intricate geometries.

- Superior Measurement Precision: Micro-focus X-ray source and advanced EFP algorithm enable accurate analysis on tiny spots (as small as 0.01mm²) and multi-layer coatings.

- Intelligent Distance Compensation: Sophisticated zoom and correction technology ensures consistent accuracy across varying measuring distances from 0-90mm.

- Advanced Spectral Resolution: Proprietary spectrum decomposition software minimizes adjacent element interference, delivering superior detection limits and result stability.

- Industrial Robustness: Built for demanding environments, featuring a durable design and a high-precision manual platform for reliable daily operation.

Key Features:

- Multi-Layer & Multi-Element Analysis: Simultaneously measures the thickness and composition of complex multi-layer coatings, including the same element in different layers.

- Wide Elemental Range: Capable of analyzing elements from Lithium (Li) to Uranium (U).

- Flexible Collimation: Optional collimators (e.g., φ0.2mm, φ0.7mm) allow for spot size optimization based on application needs.

- Plating Bath Analysis: Provides accurate concentration analysis for plating bath solutions, essential for process control.

- User-Friendly Operation: Intuitive software guides the user through the measurement process, ensuring ease of use and reducing operator error.

Application Scenarios of the XRF Spectrometer

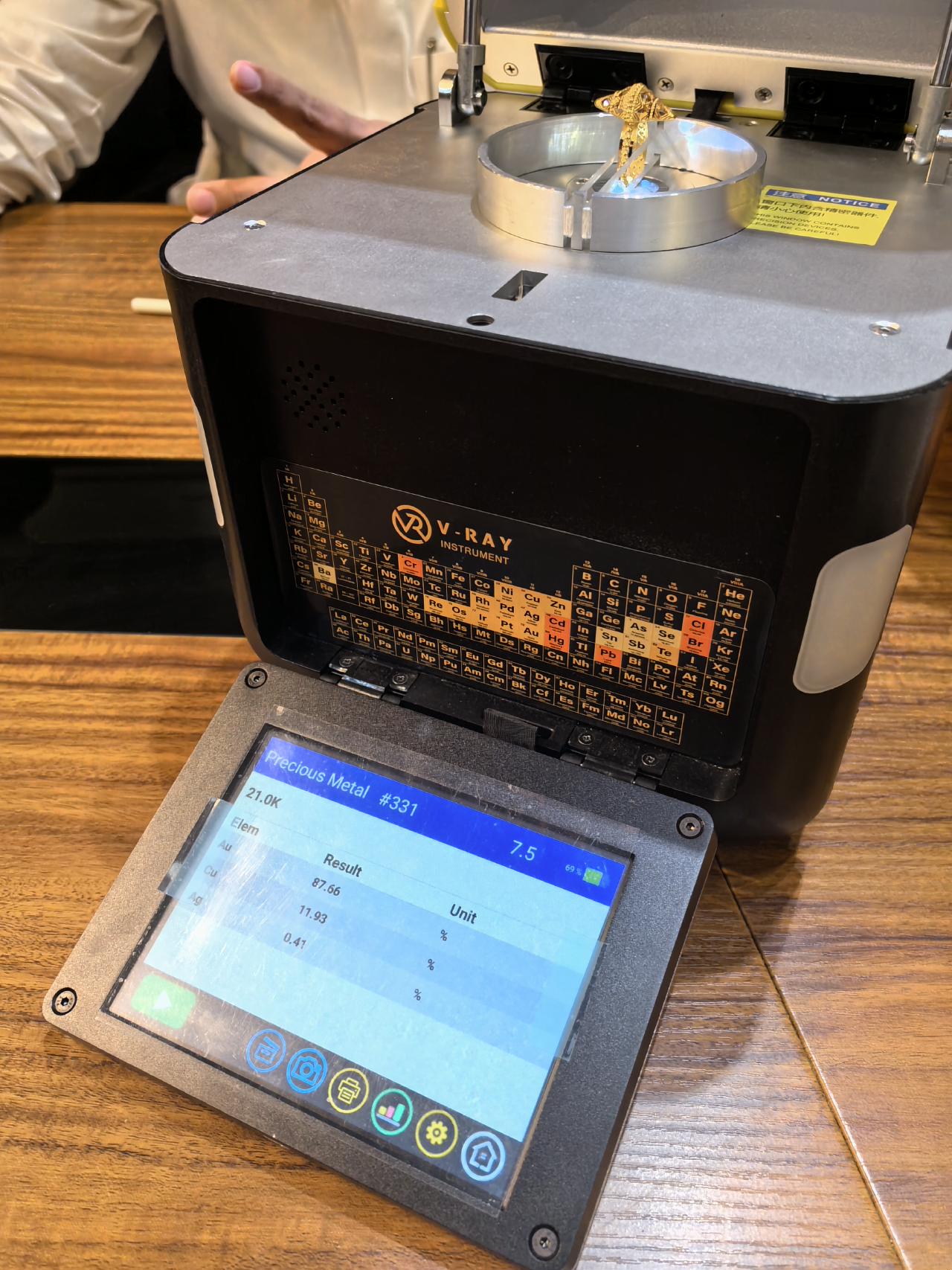

Jewelry shop

Quickly verify gold, silver, and platinum for reliable transactions.

Refineries

Ensure metal composition and purity for efficient refining processes.

Laboratories

Conduct accurate XRF analysis without damaging valuable samples.

Pawn shops

Detect metals and coatings quickly to secure trades and build trust.

Educational Institutions – Teaching and Research with XRF Technology

Train students and researchers in precise, non-destructive analysis.

Industrial Applications

Monitor metal quality and plating layers to meet industry standards.Technical Service & Warranty Items

Online Technical Support

Remote Diagnosis Service

1-Year Standard Warranty

Extended Warranty Options

Calibration Service

Software Lifetime Upgrade

Spare Parts Supply

On-Site Training Service

Maintenance Service Package

Fast Response Service