Precious Metal Tester, Coating Thickness Analysis Devices

Our XRF analyzers are designed to provide fast, accurate, and non-destructive testing for a wide range of applications in the precious metals industry. From jewelry shops and pawn shops to refineries, laboratories, and industrial facilities, these devices deliver precise analysis of gold, silver, platinum, palladium, and alloys. With the added ability to detect plating layers and measure coating thickness, they ensure quality control and authenticity verification. Easy to operate, durable, and highly efficient, VRAY instruments are trusted by professionals worldwide to support reliable testing and secure business operations.

Precious Metal Analyzer

VR-S6

VRAY Compact Benchtop XRF Spectrometer VR‑S6 – High‑Resolution Precious Metal Analyzer

View More

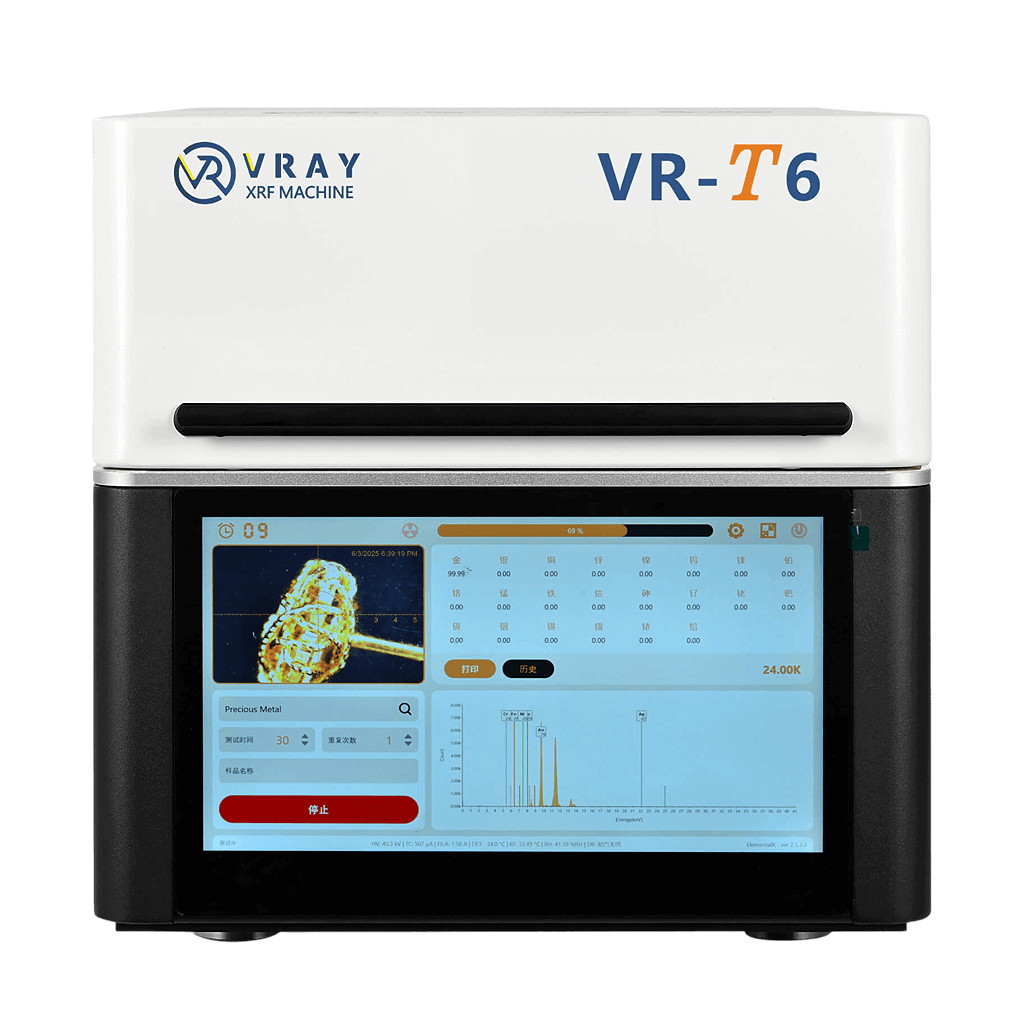

VR-T6

VRAY Bench-top big chamber XRF Analyzer VR-T6, X-ray Fluorescence Spectrometer for Precious Metal Analysis

View More

VR-T7

VRAY Bench top high resolution XRF Spectrometer VR-T7 with Manual X-Y Platform Making Micro-Area Measurement

View More

VR-Y5

VRAY XRF Gold Tester All-in-one Model VR-Y5 Precious Metal Analyzer

View More

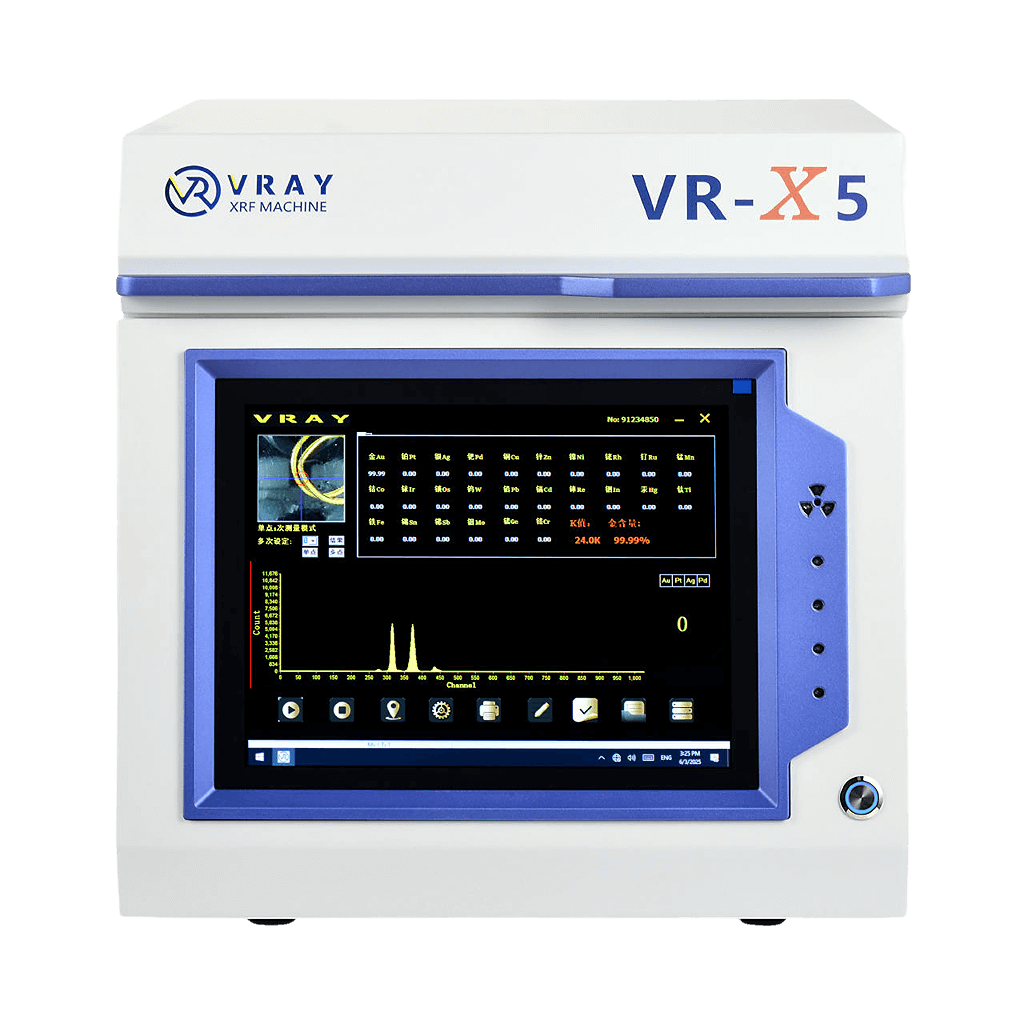

VR-X5

VRAY XRF Gold Analyzer VR-X5 delivers easy, reliable , accurate analysis for Precious Metals

View More

VR-X3

VRAY XRF Gold Tester VR-X3 Gold Analyzer

View More

VR-T9

VRAY Benchtop XRF Spectrometer VR-T9 99999 Gold Analyzer Multi-collimators

View More

VR-M5

VRAY Portable XRF Analyzer VR-M5 only 4KG Weight for onsite gold analysis.

View More

VR-M7

VRAY Portable Precious Metals Analyzer VR-M7 high precision on-site XRF spectrometer

View More

VR-H5

VRAY Handheld Precious Metals Analyzer VR-H5 1.6KG Weight on-site XRF spectrometer.

View More

VR-H7

VRAY Handheld Precious Metals Analyzer VR-H7 high precision on-site XRF spectrometer

View More

VR-H9

VRAY Handheld XRF Mineral Analyzer VR-H9 X-Ray Fluorescence Spectrometer for Ore testing

View More

VR-S9

VRAY XRF Gold Tester VR-S9 Gold Analyzer

View More

VRAY Analytical Instruments Overview

VRAY Analytical Instruments represent the pinnacle of precision and innovation for modern scientific and industrial applications. Our comprehensive portfolio encompasses a diverse range of high-performance spectrometers, chromatographs, particle size analyzers, and advanced environmental monitoring systems, engineered to deliver uncompromising data accuracy and operational reliability. Each instrument integrates cutting-edge sensor technology, intuitive software, and robust construction to meet the rigorous demands of laboratory research, quality control, and process optimization across pharmaceuticals, biotechnology, chemical manufacturing, and environmental sectors. VRAY is committed to empowering scientists and engineers with actionable insights, enabling groundbreaking discoveries, enhancing product purity, ensuring regulatory compliance, and driving sustainable operational excellence. By consistently pushing the boundaries of analytical capability, VRAY provides trusted solutions that turn complex challenges into opportunities for innovation and growth.

VRAY Precious Metal Analyzers

Precious Metal Analysis

VRAY XRF delivers fast, non-destructive testing of gold, silver, platinum, and alloys, helping jewelers, pawn shops, and refineries ensure accuracy and build customer trust.

Representative Product Models and Features: VR-S6

The VR-S6 analyzer offers high-precision EDXRF testing for gold, silver, platinum, and palladium. With fast, non-destructive analysis, intuitive interface, and plating detection capabilities, it ensures accurate and reliable results for jewelry shops, pawn shops, refineries, and laboratories.

Applications & Value

VR-S6 analyzers are ideal for quality control, authenticity verification, and elemental analysis in precious metals trading, refining, research, and industrial processes. They save time, increase efficiency, and build customer trust through consistent, accurate testing.

Selection Guide

Choose VR-S6 based on your testing needs, sample types, and throughput requirements. Whether you need analysis of coins, jewelry, ores, or alloys, VRAY offers tailored solutions to ensure precise, efficient, and reliable precious metal testing.

FAQ

Q:What accuracy range can VRAY Precious Metals Analyzers achieve across different models?

A:Depending on the mode, VRAY analyzers offer accuracy from 0.1% down to 0.001%. Entnylevel models are suitable for general gold and silver testing, while high-end models provide laboratory-arade precision for advanced analysis.

Q:How fast can a VRAY Precious Metals Analyzer deliver accurate test results?

A:Most tests are completed within 5-30 seconds, depending on the sample type and precision level required. This speed improves workfow and enhances customer confidence.

Q:Do VRAY analyzers require special preparation for testing jewelry, alloys, or powders?

A:jewelny, coins, and buk aoys require no preparation. For powders and ores, pressing samples into pelets helps achieve more stable and accurate resuts.

Q:How user-friendly are VRAY XRF instruments for daily operation in shops or labs?

A:vRAY instruments are designed with intuitive interfaces, clear displays, and simple operatin steps. Users can quicklylearn to operate the device, perform tests efficiently, and obtain accurate results without extensive training.

Q:What kind of warranty and after-sales support does VRAY provide for XRF analyzers?

A:VRAY offers comprehensive warranty coverage and professinal after-sales support. 0ur team provides remote technical assistance.training. and maintenance guidance to ensure reliable performance and long-term customer satisfaction.

VRAY Coating Thickness Analyzers (EDXRF)

VRAY Coating Thickness Analyzers are advanced XRF devices designed for fast, precise, and non-destructive measurement of metal plating and coating layers. Perfect for jewelry shops, pawn shops, refineries, laboratories, and industrial applications, these analyzers make verifying authenticity and ensuring quality control effortless. With intuitive software and ergonomic design, operators can perform tests quickly and accurately, reducing downtime and improving workflow efficiency. Reliable, versatile, and easy to use, VRAY analyzers help businesses and research institutions achieve consistent results while streamlining coating measurement processes.

Representative Product Models and Features: VR-XAU

The VR-XAU analyzer uses an advanced EFP algorithm, customized Si-PIN detector, and high-precision moving platform to deliver reliable coating thickness analysis. It supports up to 23-layer detection with fast, non-destructive results.

Applications & Value

Widely applied in jewelry, electronics, electrical machinery, and automotive industries, VR-XAU ensures quality control, cost savings, and regulatory compliance. It helps identify defects quickly and maintains high standards in production.

Selection Guide

VR-XAU is the right choice for users needing professional coating and multi-layer analysis. With humanized software, low-light focusing, and accurate zoom detection, it offers precision, efficiency, and confidence for daily operations.

FAQ

Q:How accurate are VRAY XRF Coating Thickness Analyzers for measuring plating layers?

A:VRAY analyzers deliver precise caing thickness measurements with reliable repeatabilily. Depending on the model and material, accuracy typically range fromsub-micron levels to a few microns.

Q:Can VRAY analyzers measure multiple coating layers on complex or irregular samples?

A:Yes.VRAY analyzers can measure up to 23 cating lavers simutaneously. They are equipped with advanced algorthms and zoom functins to handle uneven or special-shaped samples effectively.

Q:What types of metals and coatings can VRAY analyzers detect and analyze?

A:Thev can test aold siver patinum oaladium, nicke, coppet and other base and precious metals, This versallily makes them sultabe forieweln. eleclonics automotive, and aerospace industries.

Q:How fast can VRAY analyzers deliver coating thickness results during testing?

A:Most measurements are completed within 10-20 seconds,depending on the number of lavers and precision required.This speed supports eficient worklows in production and quality control.

Q:Which industries benefit most from VRAY XRF Coating Thickness Analyzers?

A:Jewelny, pawn shops, electronics, automotive, aerospace,and research industries benet by ensuring quat standards, detecting deects, and improving costefficiency

Ore and Powder Element Testing

Analyze ores and mineral powders with precision. VRAY XRF provides clear elemental results, empowering laboratories, mining, and research to work efficiently and confidently.

Ores and Powder Analyzers

VRAY Ores and Powder Analyzers are advanced XRF instruments designed for precise, fast, and non-destructive analysis of mineral powders, ores, and complex samples. Ideal for laboratories, mining operations, research institutions, and industrial applications, these analyzers provide accurate elemental composition results to support material evaluation, quality control, and scientific research. Capable of detecting multiple elements simultaneously, they streamline analysis workflows while ensuring reliable and reproducible data. With user-friendly software, durable construction, and professional-grade performance, VRAY analyzers empower users to conduct detailed analysis efficiently, improve productivity, and maintain high standards in research and industrial testing.

Representative Product Models and Features: VR-H9

The VR-H9 analyzer is designed for accurate elemental analysis of ores, mineral powders, and complex samples. Equipped with a high-performance X-ray tube and advanced detector, it provides fast, reliable, and non-destructive testing with wide elemental coverage.

Applications & Value

VR-H9 is widely used in mining, laboratories, research institutions, and quality inspection. It enables precise ore evaluation, supports exploration, and ensures efficient material analysis, helping industries save time and achieve reliable results.

Selection Guide

Choose VR-H9 if your work involves testing mineral powders, ores, or alloy mixtures requiring accurate composition results. Its efficiency, stability, and ease of use make it the ideal choice for both research and industrial applications.

FAQ

Q:Can VRAY analyzers handle finely crushed ore powders and homogenized mineral samples?

A:Yes. They are specificaly designed for powders, res, and pressed pelets. This ensures stable, reproducible resuts even with complex geological samples

Q:What elements can VRAY Ores and Powder Analyzers detect during analysis?

A:They can measure a wide range of elements, typically from Al(13) to U (92). This makes them suitable for mining exploration, geoscience, and industrial applications.

Q:Do VRAY analyzers require special sample preparation for powders and ores?

A:For best results, powders are often pressed into pelets with a binder. However,buk samples can also be tested directly without extensive preparation.

Q:Are VRAY analyzers suitable for use in mining exploration and industrial testing?

A:Absolutely,. They support mining operations, geological prospecting, qualily inspection,and industriallaboratories, delivering reiable elemental analysis across applications.

Q:What maintenance is needed to ensure accurate performance over time?

A: Maintenance is simple. Reqular callbration and cleaning the chamber are recommended. VRAY also provides remote supor and professional service when needed.