EDXRF Spectrometer for Coating Thickness Analysis

The VR-XAU EDXRF Spectrometer delivers precise, non-destructive coating thickness and composition analysis. Utilizing advanced EFP algorithm and microfocus X-ray technology, it efficiently measures multi-layer coatings (up to 23 layers) on various substrates, ensuring quality control and compliance in industries such as jewelry, electronics, and automotive manufacturing.

Specifications

Up to 23 layers simultaneously

Coating Analysis

Highly sensitive lens, manual focus

Focus Mode

K(19) to U(92)

Element Analysis Range

Optical 38-46X, Digital 200-400X

Magnification

Advanced EFP algorithm

Core Algorithm

High precision XY moving platform (50mmx50mm)

Moving Platform

Customized Si-PIN Detector

Detector Type

210mm

Chamber Height

Microfocus X-ray tube

X-ray Tube

545x380x435mm

Machine Dimensions

Φ0.5mm

Collimator Size

48KG

Weight

0-30mm (with distance compensation function)

Measuring Distance

DIN ISO 3497, DIN 50987, ASTMB568

Compliance Standards

1/2.7” Color CCD with Zoom function

Sample Observation

VR-XAU Coating Thickness Analyzer: Precision and Performance for Multi-Layer Coating Measurement

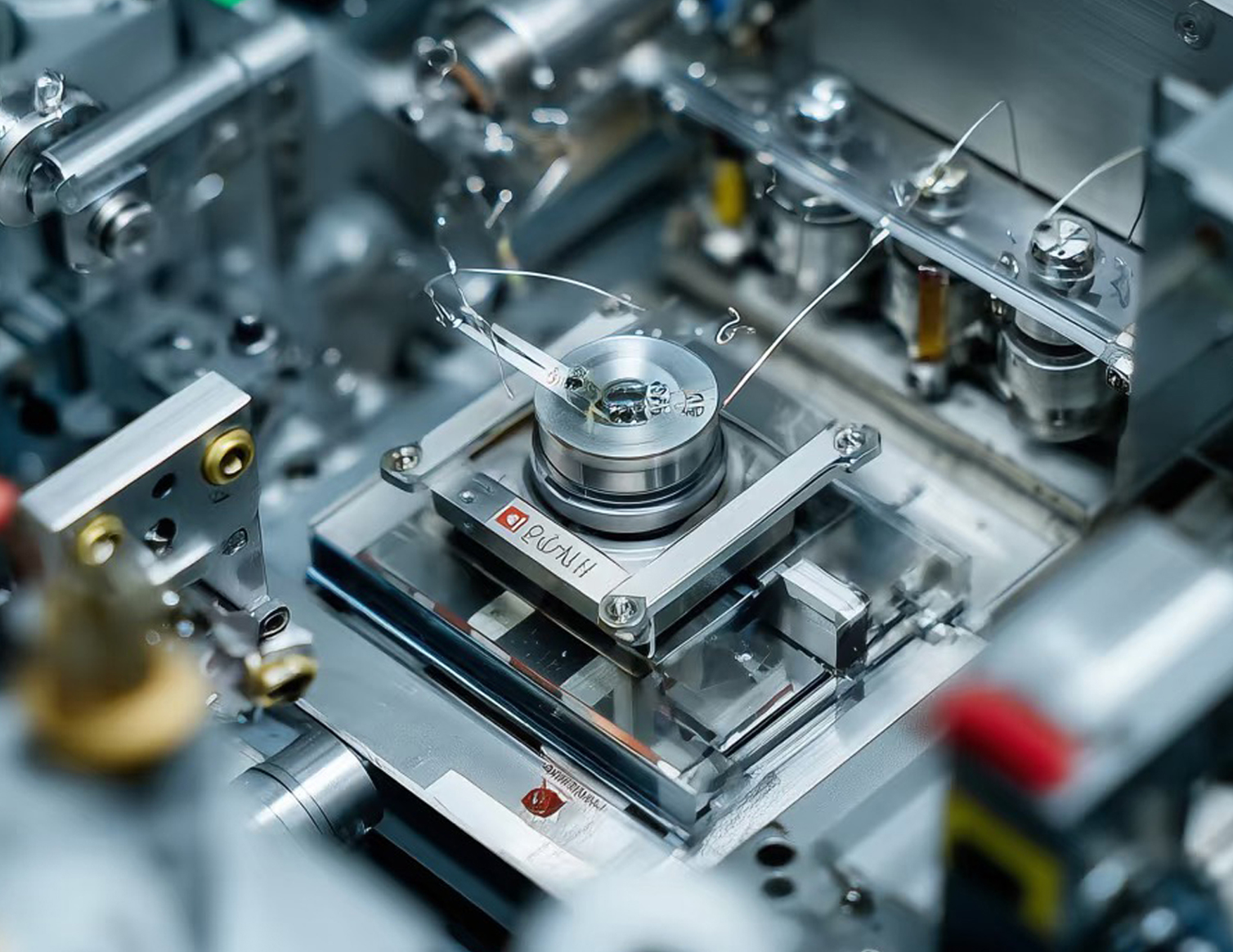

The VR-XAU is an advanced EDXRF (Energy Dispersive X-Ray Fluorescence) coating thickness analyzer designed for high-precision, non-destructive measurement of single and multi-layer coatings on various substrates. Combining state-of-the-art hardware with intelligent software, it delivers reliable results for quality control, process optimization, and compliance verification across a wide range of industries.

Equipped with a microfocus X-ray tube and a high-resolution Si-PIN detector, the instrument supports simultaneous analysis of up to 23 coating layers with exceptional accuracy—down to sub-micron levels. Its advanced EFP algorithm ensures stable and repeatable measurements even on complex or curved surfaces.

Key features include a high-precision XY moving platform for automated multi-point measurement, an integrated color CCD camera with manual zoom and focus capabilities, and low-light focusing technology for consistent spot alignment. The user-friendly software automatically detects operational errors and provides guidance, reducing training time and minimizing mistakes.

The VR-XAU meets international standards including DIN ISO 3497, ASTM B568, and DIN 50987, making it an ideal solution for applications in precious metal plating, electronics, automotive, and aerospace manufacturing. Its robust design and sophisticated analytical capabilities make it a cost-effective tool for enhancing product quality and manufacturing efficiency.

Rapid Testing

Get results within 30 seconds, greatly improving efficiency.

Versatile Applications

Suitable for a wide range of use cases.

High-Precision Analysis

Advanced algorithms and optical systems ensure accuracy and reliability.

Non-Destructive Testing

Non-contact analysis preserves samples intact.

VR-XAU: Unmatched Precision in Coating Thickness Measurement

The VR-XAU Coating Thickness Analyzer sets a new standard for accuracy and efficiency in non-destructive coating analysis. It combines advanced hardware with intelligent software to deliver reliable, multi-layer measurement capabilities for a wide range of industrial applications.

Core Advantages:

- Multi-Layer Analysis: Simultaneously measures up to 23 coating layers, providing comprehensive data in a single test.

- Advanced EFP Algorithm: Ensures highly stable and repeatable results, even on curved or complex sample surfaces.

- Non-Destructive Testing: Analyzes coatings without damaging the sample, ideal for quality control on finished products.

- Regulatory Compliance: Meets international standards (DIN ISO 3497, ASTMB568, DIN 50987), ensuring globally recognized results.

Key Features:

- High-Resolution Components: Utilizes a microfocus X-ray tube and a customized Si-PIN detector for superior sensitivity and detail.

- Precision Movement: Equipped with a high-accuracy XY moving platform (50mmx50mm) for automated multi-point mapping.

- Enhanced Visualization: Features a color CCD camera with manual zoom (optical 38-46X, digital up to 400X) and focus for precise spot placement.

- Intelligent Software: User-friendly interface automatically diagnoses faults and guides operation, reducing human error.

- Versatile Measurement: Distance compensation function allows accurate analysis of uneven and special-shaped samples.

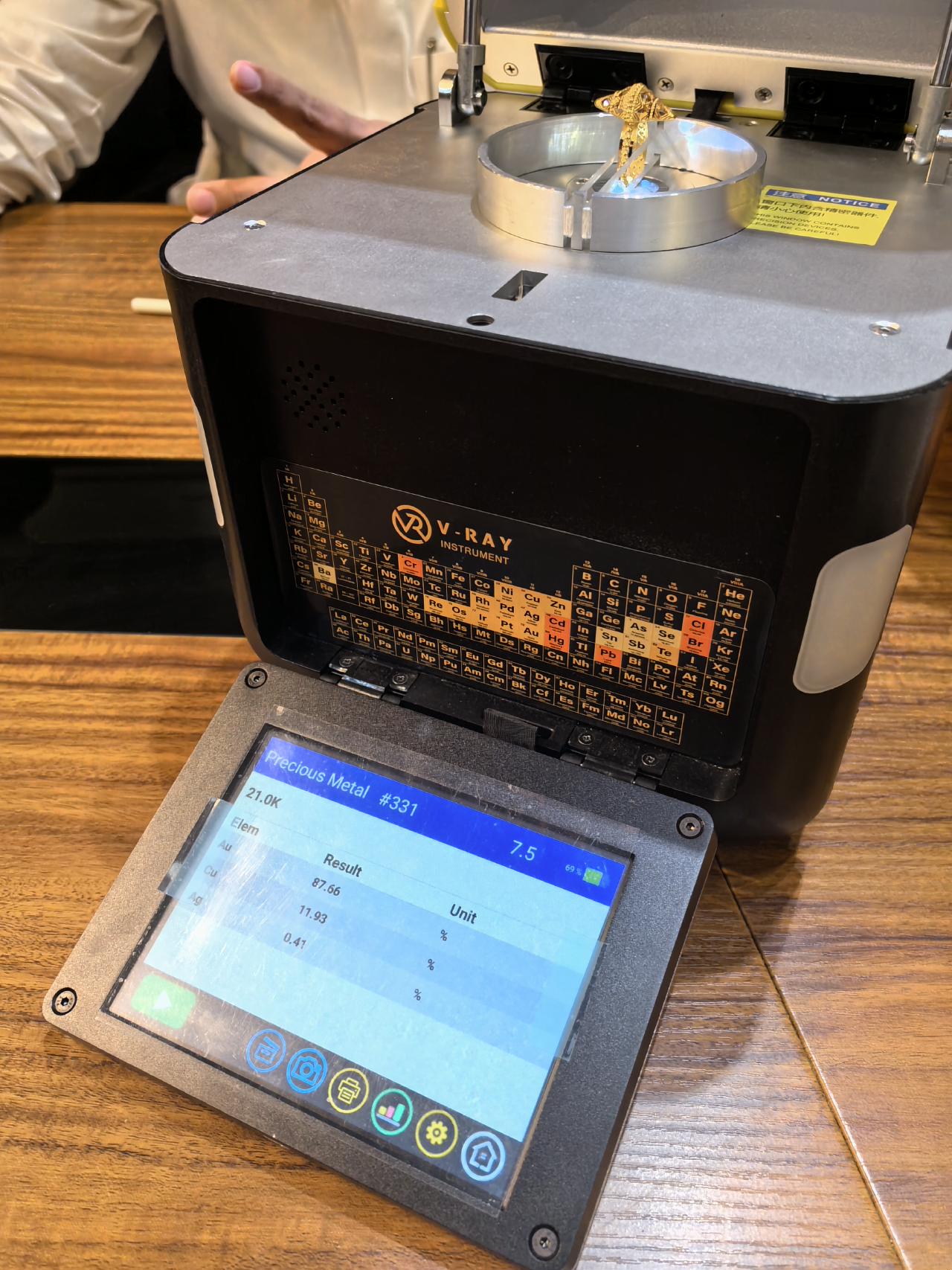

Application Scenarios of the XRF Spectrometer

Jewelry shop

Quickly verify gold, silver, and platinum for reliable transactions.

Refineries

Ensure metal composition and purity for efficient refining processes.

Laboratories

Conduct accurate XRF analysis without damaging valuable samples.

Pawn shops

Detect metals and coatings quickly to secure trades and build trust.

Educational Institutions – Teaching and Research with XRF Technology

Train students and researchers in precise, non-destructive analysis.

Industrial Applications

Monitor metal quality and plating layers to meet industry standards.Technical Service & Warranty Items

Online Technical Support

Remote Diagnosis Service

1-Year Standard Warranty

Extended Warranty Options

Calibration Service

Software Lifetime Upgrade

Spare Parts Supply

On-Site Training Service

Maintenance Service Package

Fast Response Service