Precious Metal Analyzer VR-T7, Manual X-Y for Micro-Area

The VR-T7 benchtop analyzer delivers ultra-precise (±0.01%(9999gold)) precious metal testing with a manual X-Y platform (25µm precision) for micro-area measurement. Equipped with a SDD detector and large chamber, it supports solids/liquids/powders, ideal for jewelry, alloys, and quality control labs.

Specifications

330 × 580 × 360 mm

Product Dimensions

High-resolution CMOS color camera

Camera

320 × 480 × 130 mm

Sample chamber size

AC 100V~220V±5V 50Hz

Power supply

50W (50 kV, 1mA) micro-focused beryllium window

X-ray Tube

100W

Rated Power

High sensitivity SDD detector

Detector

10℃-35℃

Operating Temperature

φ1.5mm

Collimator

40% – 70% (Non-condensing)

Humidity

Moving range: 50×50 mm, Precision: 25 µm

Manual XY Platform

K (19) to U (92)

Elemental Range

40 kg (Net) / 60 kg (Gross)

Weight

±0.01%(9999gold)

Detection Accuracy

T-shaped radiator cooling system

Safety Protection

Solids, liquids, powders

Sample Types

VR-T7 Benchtop Precious Metal Analyzer

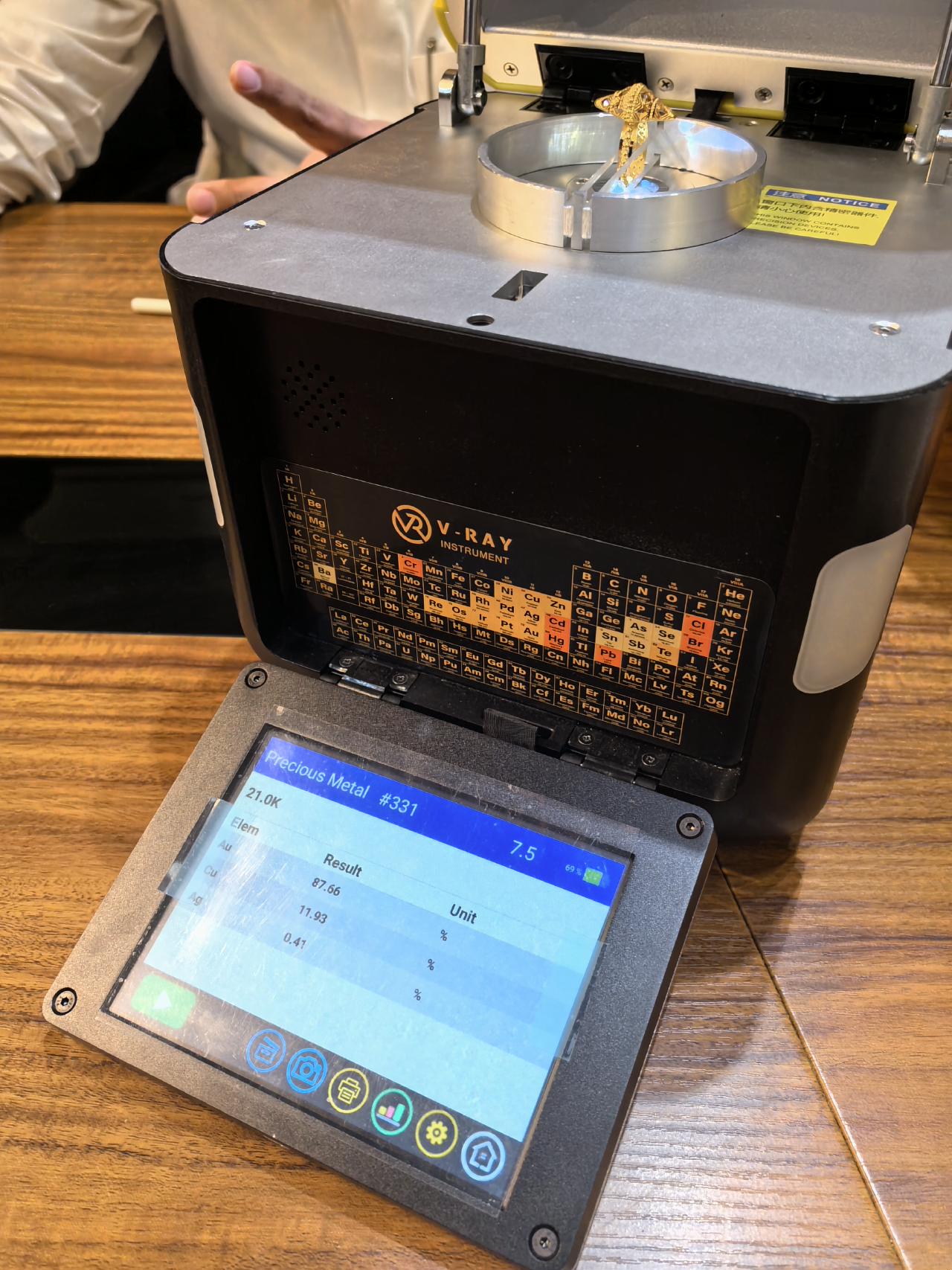

The VRAY VR-T7 is a premium benchtop X-ray fluorescence (XRF) analyzer designed for ultra-high precision analysis of precious metals, alloys, and multi-element materials. With an exceptional detection accuracy of ±0.01%(9999gold), it sets a new standard for quality control in industries such as jewelry manufacturing, metallurgy, recycling, and scientific research.

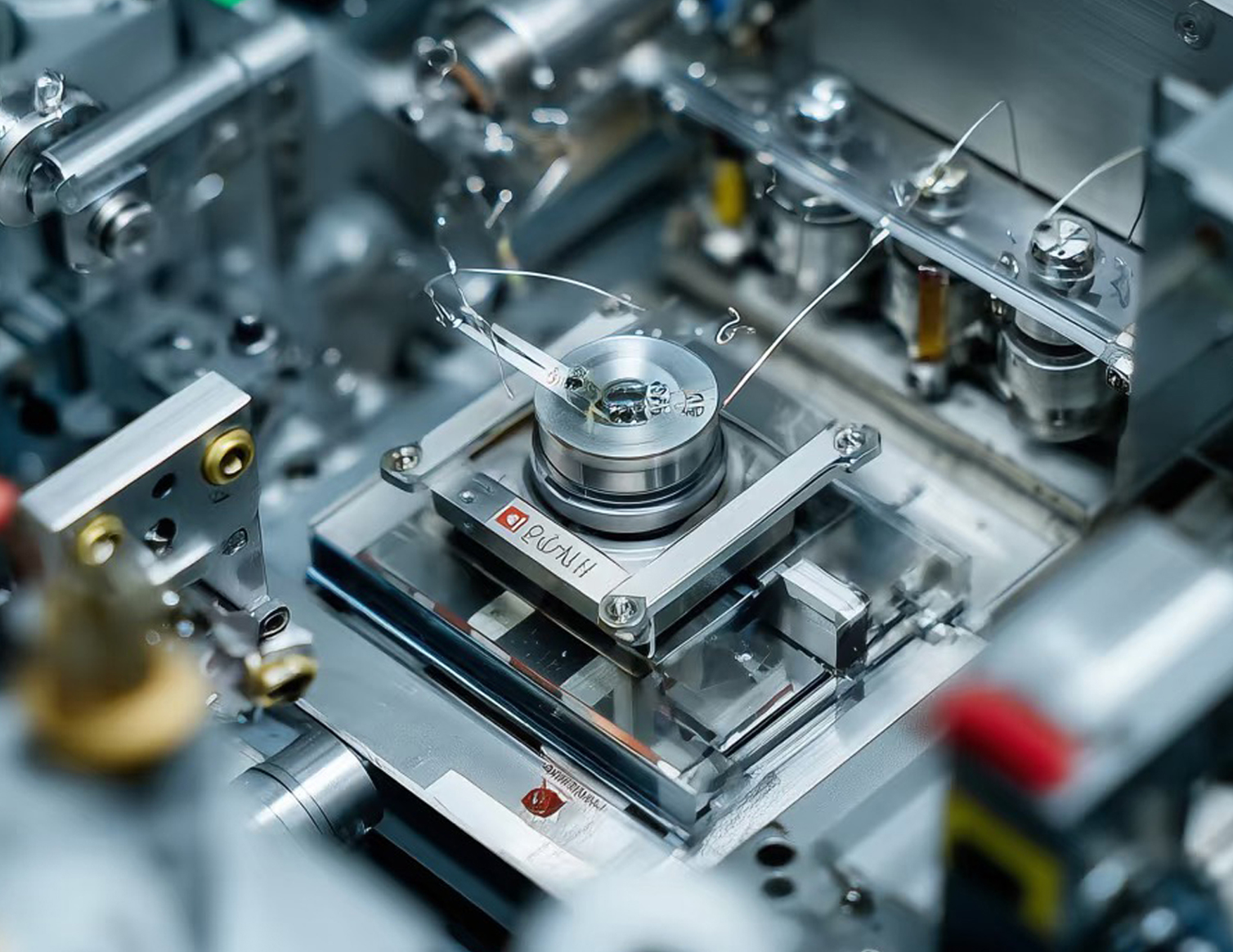

Equipped with a manual X-Y sample platform offering 25µm precision, the VR-T7 enables precise micro-area measurement—ideal for small components, intricate jewelry designs, and localized material analysis. The large testing chamber (320 × 480 × 130 mm) accommodates solids, liquids, and powders, supporting non-destructive testing without complex preparation.

At the heart of the VR-T7 is a high-sensitivity SDD detector and a 50W micro-focused X-ray tube with a beryllium window, ensuring rapid and reliable elemental analysis from potassium (K) to uranium (U). The advanced Fundamental Parameter (FP) algorithm enhances spectral resolution and reduces detection limits, while a φ1.5mm collimator delivers focused excitation for improved accuracy.

User-centric features include a CMOS color camera for clear sample positioning and documentation, an intuitive software interface with one-click operation, and compatibility with various connectivity options (USB, HDMI, LAN). The built-in radiation protection system, T-shaped cooling radiator, and safety interlock mechanism ensure operator safety and instrument durability.

Applications range from gold fineness verification and alloy composition analysis to educational training. Supported by VRAY’s global technical service and warranty program, the VR-T7 combines cutting-edge technology, rugged construction, and unparalleled precision for professionals who demand the best in material analysis.

Rapid Testing

Get results within 30 seconds, greatly improving efficiency.

Versatile Applications

Suitable for a wide range of use cases.

High-Precision Analysis

Advanced algorithms and optical systems ensure accuracy and reliability.

Non-Destructive Testing

Non-contact analysis preserves samples intact.

Core Advantages & Key Features of VR-T7

The VR-T7 sets a new standard in precision material analysis with its ultra-high accuracy micro-area measurement capability and advanced detector technology, designed for demanding professional applications.

Core Advantages:

- Ultra-Precise Detection: ±0.01%(9999gold) accuracy for precious metal analysis

- Micro-Area Measurement: Manual X-Y platform with 25µm precision

- Advanced Detection Technology: High-sensitivity SDD detector

- Large Sample Compatibility: Spacious chamber handles solids/liquids/powders

- Enhanced Safety Systems: Radiation protection and T-shaped cooling

- Professional Grade: Meets stringent quality control requirements

- Non-Destructive Testing: Preserves sample integrity

Key Features:

- Elemental range: K (19) to U (92)

- 50W micro-focused X-ray tube with beryllium window

- φ1.5mm collimator for precise beam focusing

- CMOS color camera for sample visualization

- Manual XY platform with 50×50mm movement range

- Windows-based software with intuitive interface

- Multiple connectivity: USB, HDMI, LAN

- Applications: jewelry, alloys, recycling, research, education

- Real-time data export and report generation

- Supported by global technical service network

Application Scenarios of the XRF Spectrometer

Jewelry shop

Quickly verify gold, silver, and platinum for reliable transactions.

Refineries

Ensure metal composition and purity for efficient refining processes.

Laboratories

Conduct accurate XRF analysis without damaging valuable samples.

Pawn shops

Detect metals and coatings quickly to secure trades and build trust.

Educational Institutions – Teaching and Research with XRF Technology

Train students and researchers in precise, non-destructive analysis.

Industrial Applications

Monitor metal quality and plating layers to meet industry standards.Technical Service & Warranty Items

Online Technical Support

Remote Diagnosis Service

1-Year Standard Warranty

Extended Warranty Options

Calibration Service

Software Lifetime Upgrade

Spare Parts Supply

On-Site Training Service

Maintenance Service Package

Fast Response Service