How Can You Tell if Gold Is Fake Without Chemicals?

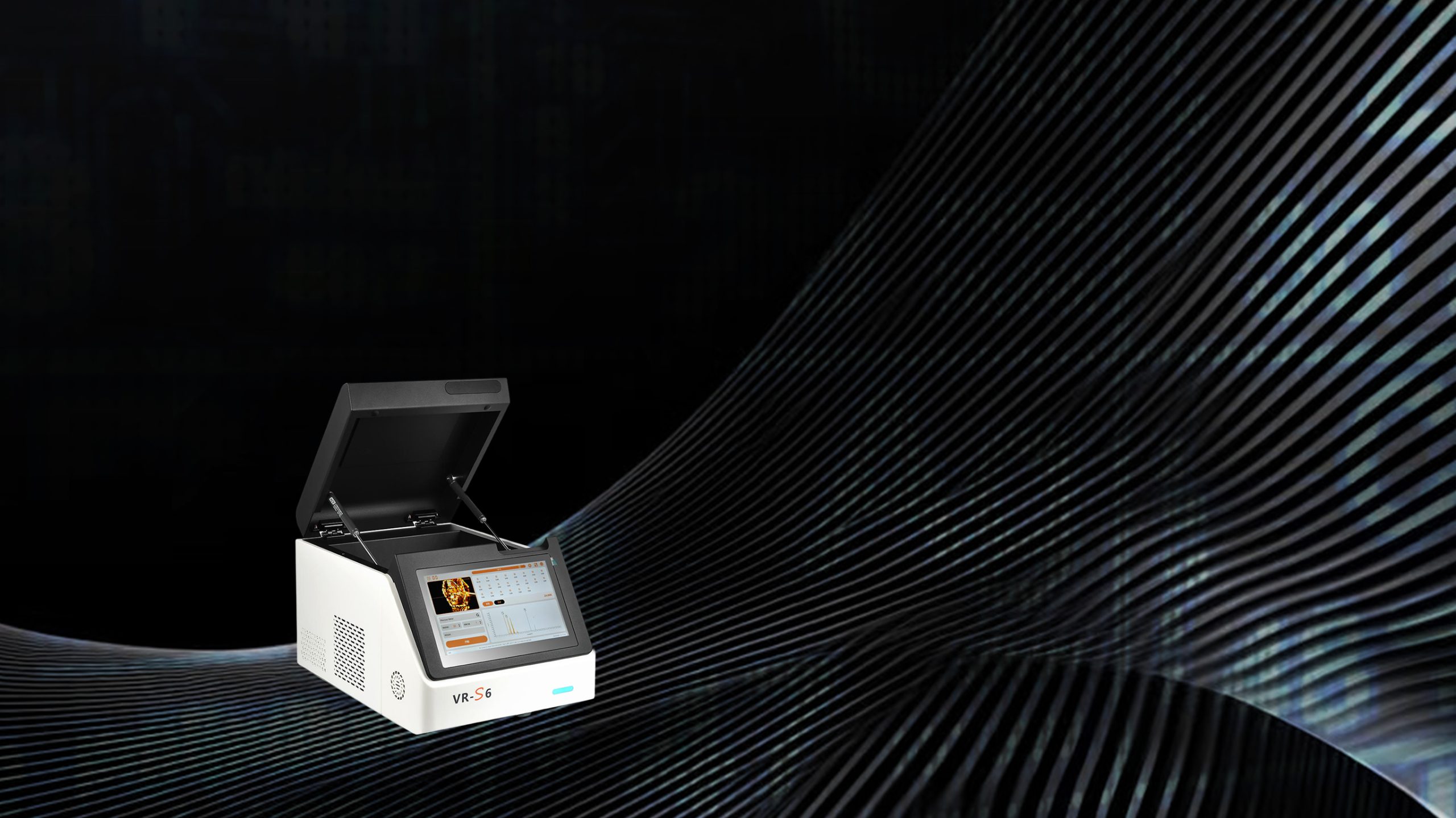

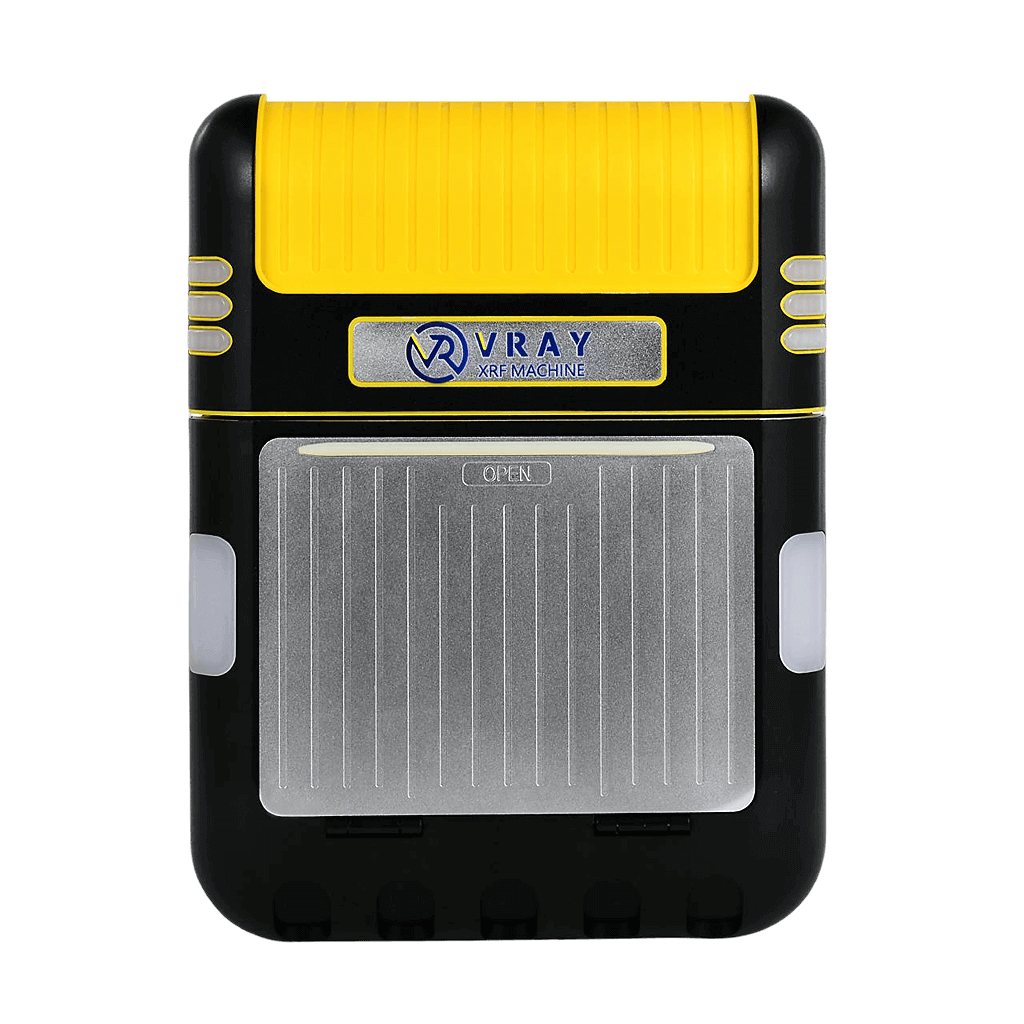

Spotting fake gold can be surprisingly difficult, especially when counterfeiters use convincing plating techniques or mix alloys that look nearly identical to real gold. Many people assume that chemical acid tests are the only way to confirm authenticity, but there are practical, non-chemical methods that anyone can use to identify fake gold safely. Whether you are a jewelry buyer, pawnshop owner, gold recycler, or simply someone who wants to ensure the value of their investment, these approaches can help you test gold quickly and without damaging it. 1. Simple At-Home Ways to Check if Gold Is Fake If you don’t have access to professional testing equipment, there are several physical checks you can perform: Visual Inspection Look for Hallmarks: Genuine gold jewelry usually has purity marks such as 24K, 18K, 14K, or 10K. A missing or unclear stamp can be a warning sign. Check for Wear and Fading: Fake gold or gold-plated items often show discoloration where the plating has worn off, exposing a different metal underneath. Magnet Test Gold is not magnetic. If your jewelry is strongly attracted to a magnet, it’s a clear indication that it contains other metals. However, note that some fake alloys are also non-magnetic, so this test alone is not conclusive. Weight and Size Gold is dense and heavier than most counterfeit metals. Comparing the weight of a suspected gold piece to a verified one of the same size can reveal differences. Sound Test Real gold produces a long, soft ringing sound when struck, while fake metals often sound dull or sharp. Experienced jewelers can sometimes detect authenticity simply by listening. 2. Non-Chemical Professional Methods to Detect Fake Gold While at-home checks are useful, they often leave room for doubt. For a reliable, safe, and non-destructive result, advanced gold testing instruments are the best solution. X-Ray Fluorescence (XRF) Technology XRF gold analyzers are widely recognized as the most accurate way to identify fake gold without chemicals. They work by emitting X-rays onto the material, which causes elements within the sample to emit fluorescent radiation. This radiation is then analyzed to determine the exact composition of the metal. Completely Non-Destructive: No damage to jewelry or coins. Fast Results: Provides composition data within seconds. Highly Accurate: Can differentiate between pure gold, alloys, and gold-plated items. Portable Options: Some models are handheld, allowing jewelers, recyclers, and even mobile gold buyers to verify authenticity on the spot. 3. Why XRF Gold Analyzers Are Better than Traditional Methods Many traditional non-chemical tests—such as bite marks or ceramic scratch tests—risk damaging jewelry. Even professional acid tests may corrode or discolor surfaces. By contrast, XRF analyzers: Deliver laboratory-grade precision. Detect more than just gold—they also reveal silver, platinum, palladium, rhodium, and other alloys. Save time by eliminating the need for complex preparation. Provide documented results, which is crucial for quality control, audits, or resale transactions. For professionals in jewelry, pawnshops, refineries, and gold recycling, XRF analyzers are not just a tool but a business necessity. 4. VRAY Instruments: Advanced Solutions for