Which XRF Test Is Best for 21k Gold Jewelry?

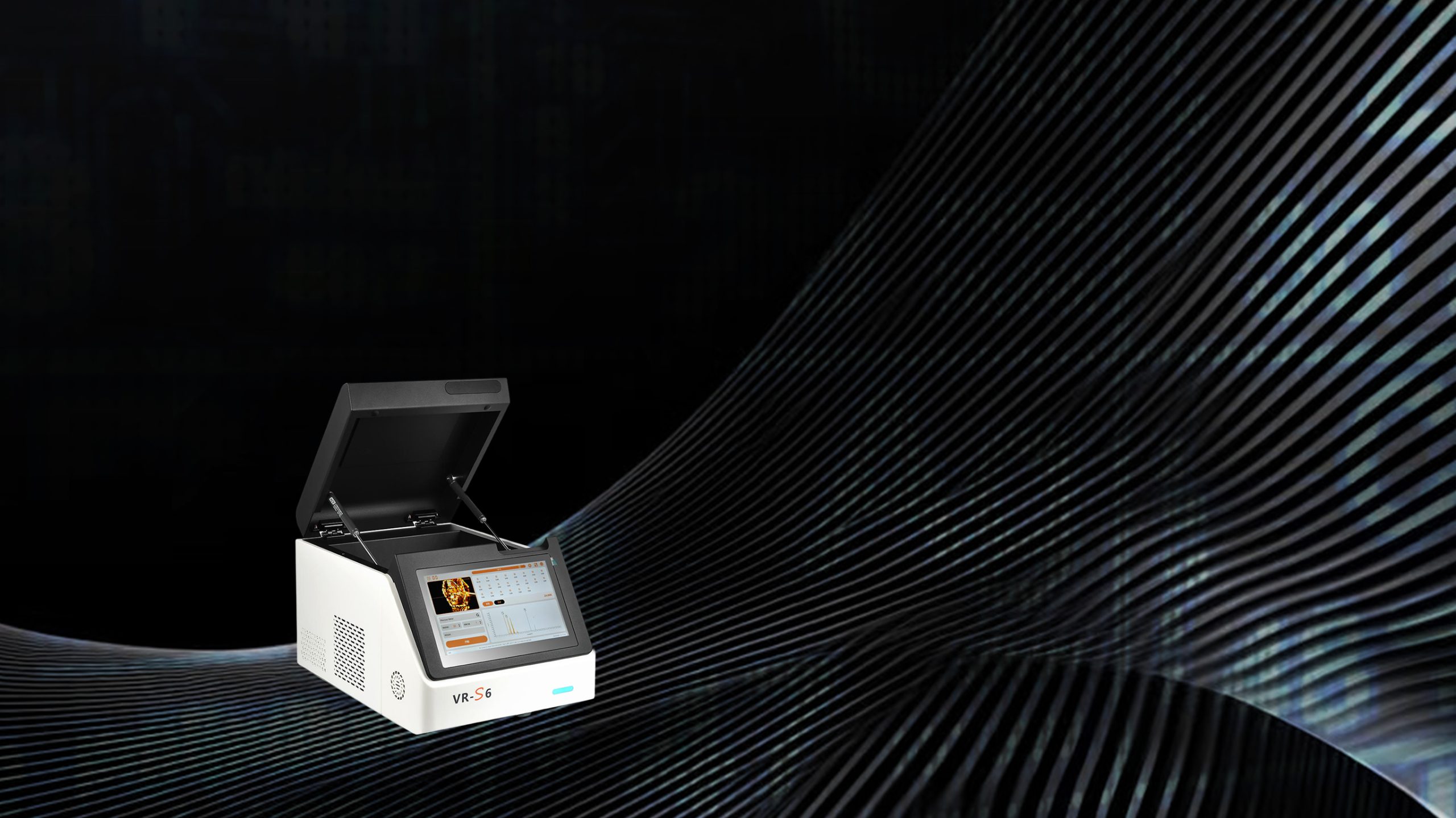

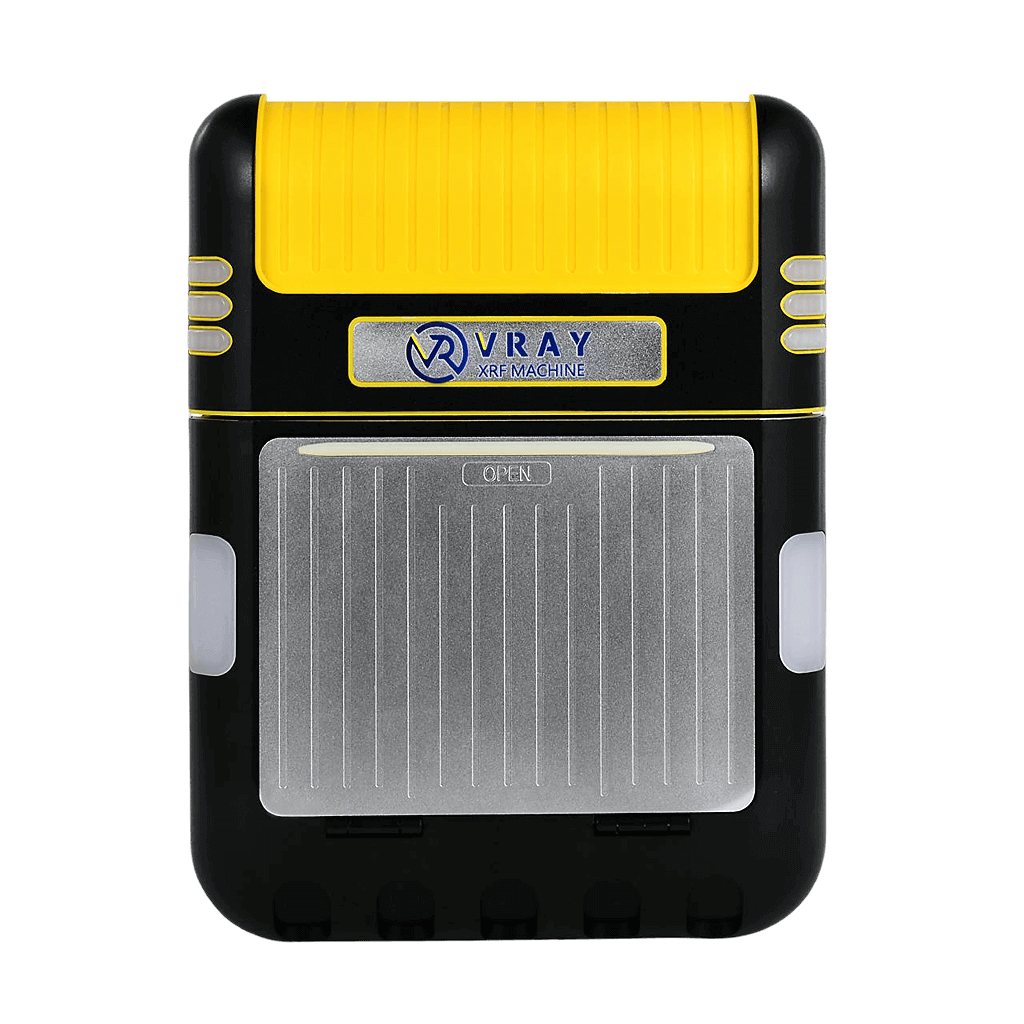

For testing 21k gold jewelry, high-sensitivity XRF analyzers equipped with specialized detectors and optimized software algorithms deliver the most accurate and efficient results. Whether you’re operating in a jewelry store, pawnshop, or quality control lab, the ideal XRF test strikes a balance between precision, ease of use, and portability—making VRAY’s line of XRF gold testers a top choice in the industry. Why 21k Gold Needs a Reliable Testing Method 21k gold is widely used in high-value jewelry across global markets. Unlike 24k gold, it contains other metals such as silver, copper, or zinc to improve strength and durability. But because its purity sits between 18k and 24k, even a minor testing error can lead to significant valuation differences—which is why XRF testing must be highly accurate. Traditional methods like acid testing are outdated and risky for valuable pieces. They’re destructive, subjective, and can’t reliably distinguish between 21k and alloys that are close in composition. XRF, on the other hand, offers non-destructive, repeatable results in just seconds, making it the preferred solution. What Makes a Great XRF Test for 21k Jewelry? To accurately test 21k gold, the XRF analyzer must meet the following requirements: Precise purity detection: The ability to detect small changes in gold concentration (down to 0.001%) is critical. Elemental sensitivity: Since 21k gold may contain other metals, the detector must reliably distinguish between gold and alloying elements. Stability and repeatability: Professional users require consistent results even across repeated tests. User-friendly operation: Touchscreen operation, pre-calibrated profiles, and intuitive software reduce training time and eliminate guesswork. Portability or lab-grade power: Depending on the use case, the device must either be portable for on-site testing or powerful for lab-grade analysis. VRAY Recommends: The Best XRF Analyzers for 21k Gold Testing 1. VR-X5 – Precision Meets Performance For jewelry stores, refineries, and gold buyers looking for lab-level accuracy in a compact benchtop unit, the VR-X5 is the top recommendation. Equipped with a custom-designed Si-PIN detector, it can test over 20 elements, making it ideal for detecting both gold content and alloys in 21k jewelry. Built-in HD screen and integrated computer No external devices needed Automatic high-voltage protection Fast analysis speed for high customer throughput Its sensitivity and precision make it a preferred choice for professionals who need results they can trust. 2. VR-T9 – Designed for Ultra-High-Purity Analysis If your business deals in high-value 21k gold and wants the most accurate measurement possible, the VR-T9 is built for you. It delivers a detection precision of ±0.001% and supports customized reports and spectrum comparison for easy identification of alloying trends. Ideal for large-volume or wholesale gold analysis Can distinguish fine differences in karat value (e.g., 20.8k vs. 21.1k) Excellent for quality control, batch analysis, and fraud detection 3. VR-H5 – Portable, Fast, and Reliable For businesses that require on-site testing, such as mobile gold buyers, pawnshops, or field inspections, the VR-H5 handheld analyzer offers unmatched flexibility without compromising performance. Lightweight and compact with touchscreen display Intelligent battery management and gravity shutdown feature Real-time