What Is the Best Gold Testing Kit for Beginners?

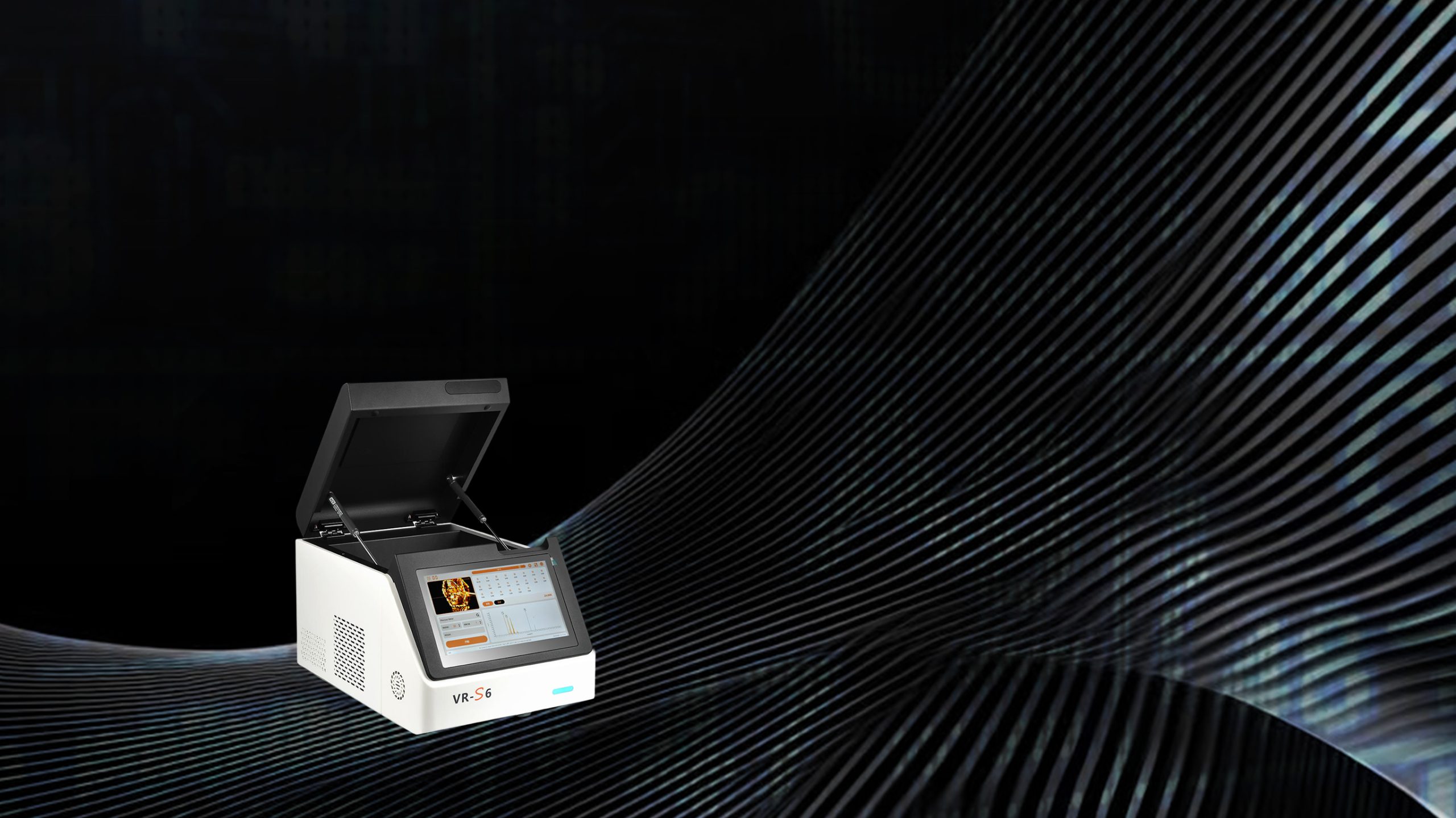

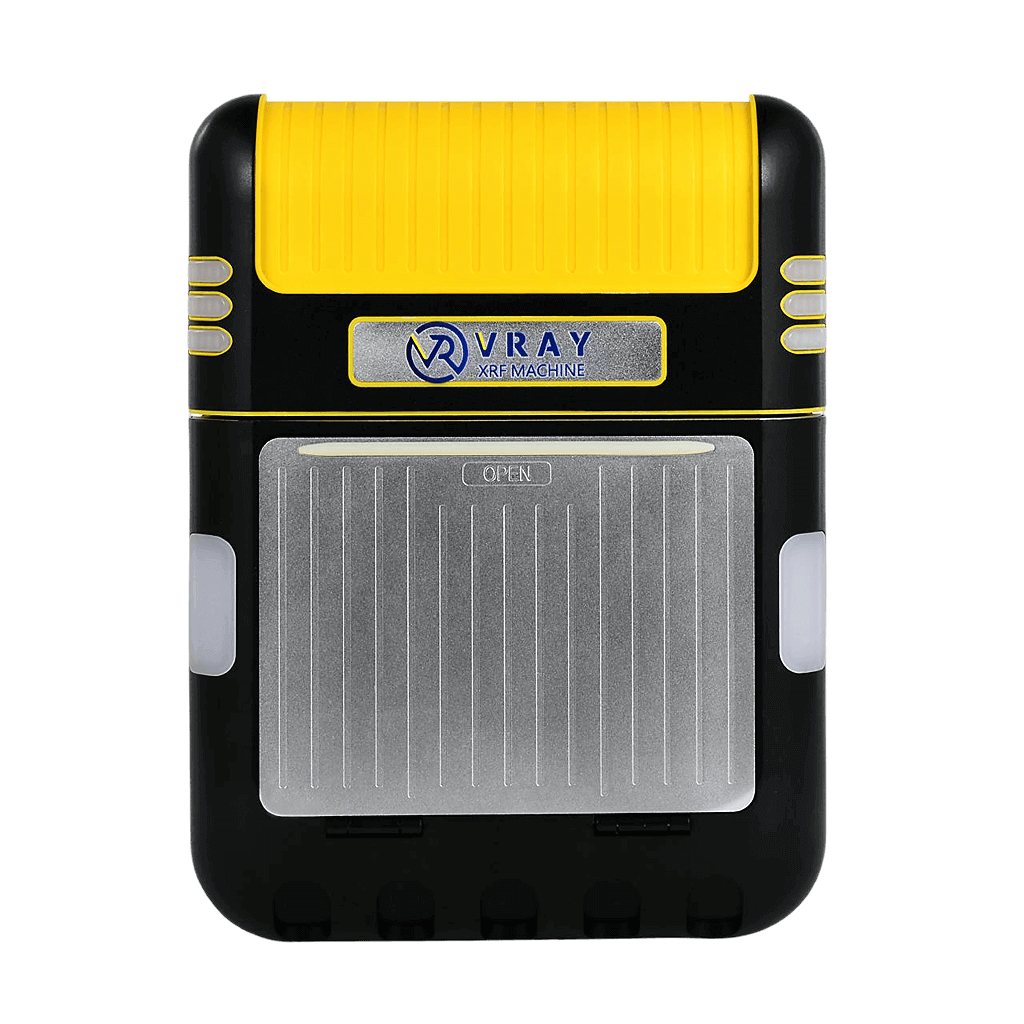

If you’re just getting started with gold testing, it’s easy to feel overwhelmed by all the options out there. After trying out multiple devices, one stood out as especially beginner-friendly: the VRAY VR-H5 handheld gold analyzer. You don’t need a technical background to use it—it works right out of the box, gives fast results, and delivers accuracy you can trust. Whether you run a small jewelry store, deal in secondhand gold, or just want to check the value of your collection, this is the perfect entry-level tool that makes gold testing easy. Why Choose a Handheld XRF Gold Tester Over Traditional Methods? For years, acid kits were seen as the go-to solution for gold testing. However, they come with several downsides—risk of false positives, corrosive chemicals, damage to the item, and the need for experience to interpret results correctly. Electronic testers, while somewhat safer, often struggle with accuracy, especially for high-karat gold or plated items. By contrast, XRF analyzers use non-destructive X-ray technology to read the elemental composition of a metal in real time. This makes them more suitable for testing finished jewelry, coins, scrap gold, and even electronic components containing trace amounts of precious metals. With just a few clicks and no sample preparation, beginners can get reliable purity readings without damaging the material being tested. Introducing the VRAY VR-H5: The Best Entry-Level XRF Gold Tester If you’re new to the gold industry and looking for a reliable way to verify gold purity, the VRAY VR-H5 is a game-changer. ✅ Key Features That Matter to Beginners: Portable and lightweight: The VR-H5 fits in one hand and can easily travel between store locations, pawn shops, or trade shows. Real-time testing: Get results in seconds with no need for acid or fire. Easy operation: Features an industrial-grade touchscreen and intuitive interface—no technical background required. Advanced safety: Built-in gravity sensing and radiation auto-shutdown enhance user safety, even for first-timers. No sample damage: Test coins, jewelry, or scrap without leaving a mark. Who Should Use the VR-H5? Independent jewelers and retail shop owners Pawn brokers and second-hand gold buyers Mobile gold recycling service providers Hobbyists and gold enthusiasts who want to verify their collection The VR-H5 is not just beginner-friendly—it’s also trusted by professionals. Its performance, portability, and protective features make it the ideal entry point into the world of professional gold testing. What Makes VRAY Instruments Different? Unlike generic testing kits or basic devices sold online, VRAY Instruments specializes in high-precision precious metal analysis. Every device is backed by a team of professionals, an industry-leading R&D department, and a reputation built on innovation and trust. Over 10 types of gold testing analyzers designed for different user levels and needs Unmatched support from technical specialists who guide you beyond the product Real-time customer service and product training upon request Regular software updates to enhance testing accuracy and interface usability With VRAY, you don’t just buy a device—you invest in a long-term testing solution tailored to your growth, whether you’re a beginner or on