What Is the Best Gold Tester for Jewelry Shops?

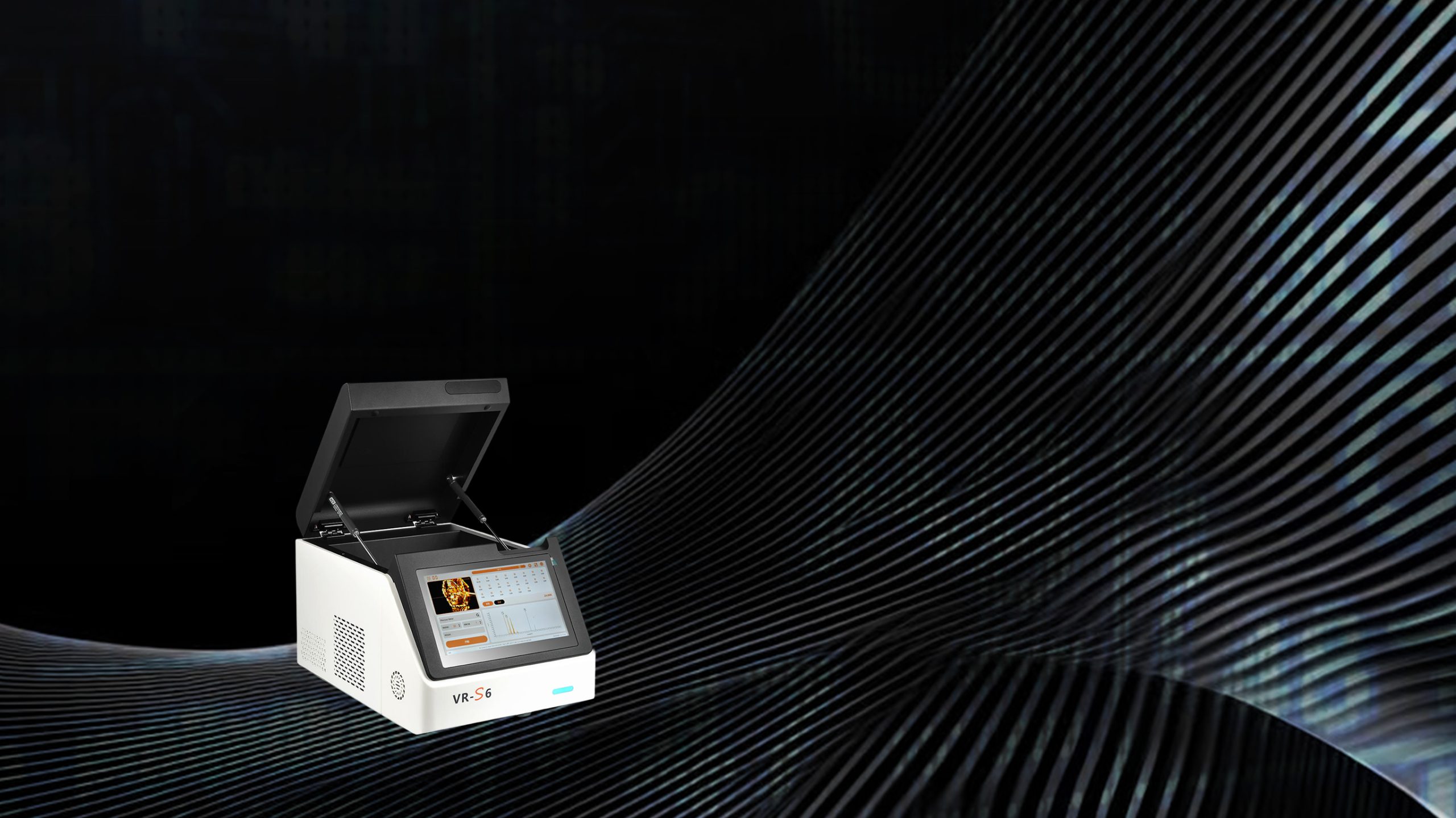

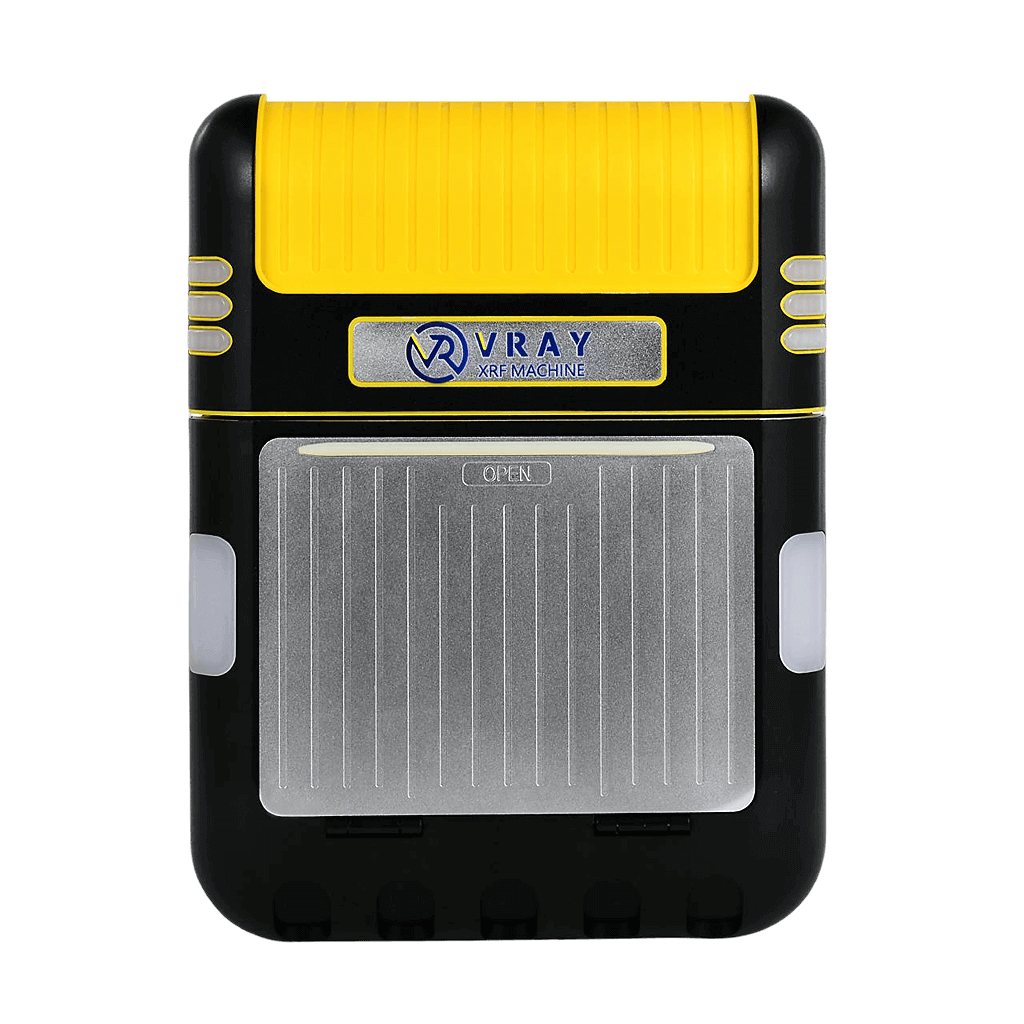

When customers walk in with gold to buy, sell, or trade, they expect one thing above all: accuracy. Whether it’s ensuring the purity of new stock or evaluating customer items, your testing device must be reliable, easy to use, and fast. So what’s the best gold tester for a modern jewelry shop? The answer lies in combining advanced technology with practical design, and few brands deliver this better than VRAY Instruments. VRAY’s range of XRF gold testers is designed for real-world usage in busy jewelry retail environments. These devices offer non-destructive testing, instant readings, and professional-grade accuracy, ensuring shop owners and customers alike can trust every result. Below, we’ll explore the key features of a great gold tester, compare the top models offered by VRAY, and help you decide which model best fits your store’s needs. What Makes a Gold Tester Ideal for Jewelry Shops? While many devices claim to measure gold purity, jewelry shops need testers that are: Accurate across a wide range of alloys and karats Fast and easy to operate, even for non-technical staff Safe and non-invasive, without damaging the item Capable of testing various shapes like rings, chains, and coins Compact and clean enough to fit in front-end retail environments Traditional acid tests are outdated—they damage items and are prone to human error. Digital gold testers based on X-ray fluorescence (XRF) technology have become the preferred method in the industry due to their speed, accuracy, and safety. Top VRAY Gold Testers for Jewelry Shops 1. VR-X3: Reliable & Affordable for Everyday Retail Use The VR-X3 is a perfect entry-level XRF gold tester tailored for jewelry shops. It offers excellent precision using a gas-proportional counter detector and is ideal for checking the purity of gold, silver, platinum, and palladium. Why it’s great for shops: Built-in industrial computer and touchscreen One-click analysis with fast results Overheat and high-voltage protection for durability Automatic interference correction for accurate readings This model is especially popular in boutique jewelry stores where staff members value simplicity and reliability. 2. VR-X5: Versatile & Precise With Advanced Detection Need more advanced detection with wider element coverage? The VR-X5 features a silicon PIN detector tailored for high-sensitivity readings. It can test over 20 elements and is perfect for gold buying, selling, and alloy analysis. Key features: Fully integrated high-definition display—no external PC needed Enhanced element range for karat identification and trace metals Accurate results within seconds Sleek design that fits well in storefronts For stores that also buy used gold or offer trade-in services, this is the ideal mid-range model. 3. VR-T5 & VR-T6: Ideal for Shops Needing Detailed Reports If your business offers premium services or certification reports for gold content, the VR-T5 and VR-T6 are strong candidates. Both are benchtop models with Multi-FP software, advanced focusing tech, and wide sample compatibility. Why they stand out: Customizable testing reports for each customer Tests gold plating and irregular jewelry shapes From-top measurement—no repositioning needed High-speed, high-accuracy, no sample prep required These models are ideal for high-end